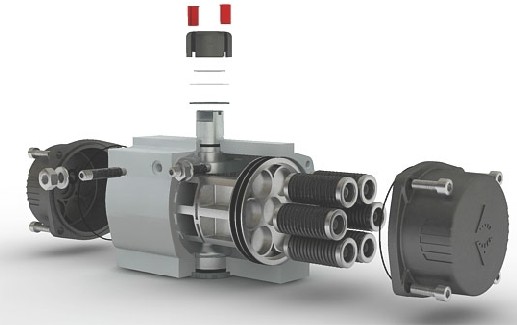

DHV Elastomeric Delta Seat (EDS) Trunnion Ball Valves.

- Western Canada’s oilsands industry provides some challenges regarding the selection of materials used in pipeline valves used for midstream applications.

- Bitumen produced from the oil sands contain complex long chain hydrocarbon molecules known as asphaltenes. These highly complex molecules make the bitumen sticky, viscous and almost rock-solid at room temperatures. Asphaltene content can vary from 10% to over 20%. Alberta’s bitumen also has a relatively high sulphur content – as much as 5%, and up to 0.5% fine solid particles.

- Diluting bitumen makes it much easier to transport using trucks, rail cars or specifically transporting via pipelines.

- Dilbit is a bitumen diluted with one or more lighter petroleum products, typically natural gas liquids or Naptha.

General Features:

- A-350-LF2 Class 1, 3 pc bolted body

- EDS seat carriers are completely interchangeable in existing DHV – forged trunnions

- All valves supplied as DIB-1 as defined by ISO/API 6D as standard with body vent plugged for future liquid port

- All valves are supplied with HNBR/Graphite – 3 level stem seal as per ISO 15848 -1 low emission specification

- Delta seat and carrier O-rings are Viton AED-GLT rated to -46C, explosive decompression compliant

- Standard trim is 3 mil, low Phosphorus ENC.

- DIB-2/Delta seat design available for ANSI 150-ANSI1500 pressure ratings.