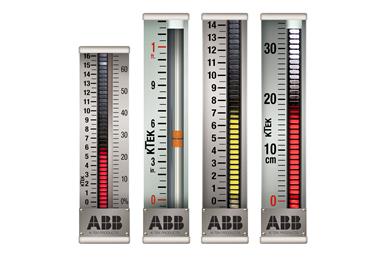

The KM26 Magnetic Level Gauge has provided custom engineered solutions to liquid level applications in industries such as: oil and gas, refinery, chemical, petrochemical, power generation and many more. The KM26 MLG has proven itself to be a safe, reliable, maintenance free solution for total and/or interface level detection in toxic, corrosive, high pressure and high temperature processes.

Features:

- Highly visible level indication with no process fluid in contact with the glass

- All construction in-house by code certified welders

- Float designed and weighted for maximum accuracy with 75 grams minimum upward buoyant force

- Transmitter and switch options which can be installed, adjusted and maintained with no process interruption

- Safe for corrosive, flammable, toxic, high-temperature and high-pressure applications

- Rugged design – low or no maintenance

Available materials:

− Stainless steel—304/304L, 316/316L, 317/317L, 321, 347, 904

− Alloy 20

− Hastelloy®—B, C-276

− Alloy 600, 625, 800, 825

− Titanium

− Teflon® (registered trademark of DuPont) coated stainless steel

− Fiberglass—epoxy or vinyl ester resin

− PVC, CPVC, Kynar®

− Polypropylene

− Zirconium

− Monel

− For other materials consult factory

Process capabilities:

− Full vacuum to 5000 PSI / 345 BAR

− -320 to 1000 °F/ -196 to 538 °C

− 0.25 specific gravity

− All liquid viscosities

− Interfaces as Low as .03 ΔSG

- Measurement & Analytics - A more measured world of water

- ABB Level products - measurement made easy brochure