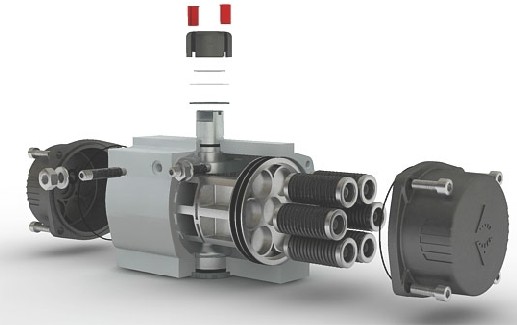

Argus Pig Valves include Model P, C, and D.

Designed to achieve optimal flow line and pipeline performance. In addition to reduced emissions, the small footprint of the Argus Pig Valve minimizes environmental impact. Compared to conventional barrel style launching and receiving traps, Argus Pig Valves are also operationally more efficient, and require less space, ultimately decreasing infrastructure costs.

Argus Pig Valves:

- Are certified under ISO 9001:2008 and API 6D, 6FA.

- Are designed in accordance with NACE/ISO, ANSI/ASME, API and MSS.

- Have a temperature range of -46°C (50º F) to +121°C (250º F).

- Are trunnion mounted, double block and bleed valves.

- Contain injection ports with double check valve in each flange.

- Contain four (4) ports to accommodate bleed valve, gauge or other accessories.

- Optional bleed valves & drain valves are available on request (not included in the quoted pig valve prices).

- Downstream pig stopper is included in all receiving valves. Optional upstream pig stopper is available on request for sending valves (not included in the quoted pig valve prices).

Benefits:

- Optimize production and mitigate corrosion through effective liquids sweeping and debris removal

- Reduce emissions by more than 80% compared to traditional launching method

- Signifi cantly smaller footprint reduces the space required for pigging facilities

- Reduced requirement for infrastructure decreases fi eld construction time

- Functionally simple design minimizes training and maintenance costs

- Double block and bleed construction facilitates use as a traditional block valve, thus reducing the number of valves required in the pigging facility

- Built in features enhance safety for operations personnel

- Adaptable to batch, corrosion inhibition programs

- Designed in accordance to NACE for sour service